What is flat roof fastening?

Flat roof fastening refers to how the insulation and membrane are secured to the roof of your building. The decision on how this is done is based on a variety of factors when evaluating the roof deck.

During a roof inspection, the consultant will find out what type of roof deck the building has. Whether your roof is single-ply, built up, modified bitumen (MBR), rubber membrane (EPDM), or something else entirely, a flat roof fastener system exists to give you the water protection, wind uplift compliance, and aesthetics your roof deck requires.

What are the different ways to fasten a flat roof?

- 1. Mechanically fastened:

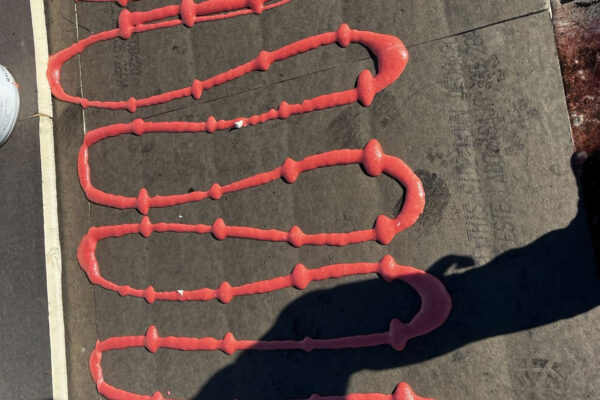

Mechanically fastening a roof system involves laying out the insulation over the roof and fastening it in place using mechanical plates and screws. Over the top of the insulation, the membrane rolls are put in place and heavy-duty fasteners are drilled through the seams of the membrane. Heavy-duty fasteners are thicker in diameter and have more threads per inch which allows them to have greater uplift strength. The heavy-duty fasteners are overlapped by the next membrane roll, and the seams are heat-welded so that no fasteners are exposed to the elements.

- 2. RhinoBond:

The RhinoBond induction weld is similar to a mechanically fastened roofing system. The main difference is the type of screws and plates used, and that none of the fasteners penetrate the roofing membrane. It is mechanically fastened through the insulation and into the roof deck. Most notably, a RhinoBond plate is used instead of a regular metal plate. A RhinoBond plate is special because in the manufacturing process, it has a coating put on it that allows a TPO or PVC membrane to be welded to it—thus creating an additional level of impermeability. - 3. Fully adhered:

A fully adhered system uses membrane/insulation compatible adhesives to adhere the insulation and/or the membrane to the roof deck to create a flat roofing system.

- 4. Ballasted:

A ballasted system uses heavy river rock to secure the insulation and membrane in place, as opposed to adhesives or mechanical fasteners. The insulation and membrane will be loosely laid in place, the seams will be made watertight, and then rock will be loaded onto the roof and evenly distributed in a way that covers the whole roof and has a minimum of 10lbs/square foot of coverage.

How do I choose which fastening option to go with?

Decisions on which fastener option to use should be made after consulting a trusted professional installer. Business owners/project managers typically take the following into consideration:

- Price

- Aesthetics

- Location/climate

- Building specifics (most notably building height)

- Warranty requirements

Note: Every roof is different. Even if one system is a good fit for a building just down the street, it may not be the right or best solution for you.

How much does each of them cost?

Without scoping the work for your particular situation, it is difficult to compare products on a cost basis. Considerations such as the tear-off required, the products being used, and the overall timeline and scope of work all play a role in the total budget.

How easy is it to perform maintenance or repairs?

| Level of Ease | Type of Fastening | Why |

| Easiest | Mechanically fastened |

|

| Easy | RhinoBond |

|

| Medium | Fully adhered |

|

| Hard | Ballasted |

|

How does insulation affect the type of fastening option I should go with?

In order to achieve the best warranty and insulation value, you will want to select insulation products that work best with your roof membrane and flat roof fasteners.

- 1. Mechanically fastened:

High level of freedom with insulation types and can install any preferred coverboards (if required). - 2. RhinoBond:

Compatible with most insulation types except those that cannot withstand the heat generated when welding such as EPS. - 3. Fully adhered:

Compatible with most insulation types except EPS. - 4. Ballasted:

Compatible with almost all insulation types but cannot accommodate high-density coverboards.

What are the benefits of each?

Mechanically fastened:

- Economical

- Fast install

- Less adhesives

- Compatible with most insulations

- Compatible with TPO, PVC, and reinforced EPDM

- Can be installed year-round

- Typical deck types: steel, wood, in some cases gypsum and concrete

Ballasted:

- Can be economical

- Fast install

- Minimal fasteners and adhesives required

- Tough to repair

- Heavy labor to spread rock

- Compatible with most insulations

- Compatible with all membranes however EPDM is preferable

- Can be installed year-round

- Typical deck types: only those rated to hold the weight of the rock used.

RhinoBond induction weld:

- Economical

- Fast install

- Fewer fasteners than mechanically fastened

- Doesn’t require parameter sheets around the edges

- Only compatible with TPO and PVC

- Can be installed year-round

- Typical deck types: steel, wood

Fully adhered:

- Pricey

- Slower install

- Minimal fastener required

- Doesn’t require parameter sheets around the edges

- Compatible with every membrane

- Not compatible with every insulation

- Cannot be installed year-round (adhesive is temperature sensitive)

- Typical deck types: steel, wood, gypsum, concrete

Does the weather in my area affect which option I should go with?

Only with regards to the installation. For mechanically fastened, ballasted, and RhinoBond, you can do all three of those fasteners regardless of temperature.

For fully adhered, outdoor temperatures need to be 40 degrees or higher for effective bonding. Some contractors work around that by heating the bonding adhesive with warmers, waiting to install when the sun is out, or switching to winter-grade products if available.

How well does each type hold up against severe weather/storms?

Each system is comparable in design and can achieve the wind uplift and hail protection you need for your particular environment and warranty. There are no bad options in this list.

When should I call a roofing contractor?

With so many factors and requirements to consider when it comes to your roof deck, insulation, and membrane, it’s always a good time to talk to a commercial roofing consultant about your needs and goals. With 64+ years of knowledge to help guide you, our sales team can provide you with all the roof details needed to achieve a long-lasting roof for years to come—a roof that’s Done for Good.